News

Published on 26 May 2011

James Willoughby

Align T Rex 450 Pro Super Combo Review and Build Guide

Introduction The T-Rex 450 Pro Super Combo is the top end Align RC helicopter. It shares very little of the core parts with the 450 Sport and 450 SE V2 varieties. Utilising a completely different frame design. Also it incorporates a tail se ... Read More

Introduction

The T-Rex 450 Pro Super Combo is the top end Align RC helicopter. It shares very little of the core parts with the 450 Sport and 450 SE V2 varieties. Utilising a completely different frame design. Also it incorporates a tail servo built into the main frame, as opposed to being mounted to the tail boom. It is aimed at the more advanced beginner or intermediate pilot due to its torque tube drive, as this provides more precise tail control, but also, increased costs in the event of a crash or boom strike. That being said, spares are plentiful, so this model can be enjoyed to its full potential without worry of high repair costs. In keeping with the increased performance of the Pro version it comes with Aligns new more powerful motor, giving this little heli a very high head-speed, in excess of 3000 rpm. So it certainly has the power to allow the user to explore some more advanced routines. The performance will be talked about in greater detail later on in this guide, but for now it’s time to get on with describing the build and reviewing the model.

Build

In keeping with the 450 Sport, Align are pre-building these models partially at the factory. With varying results, so it is imperative at the very least to check every meta-metal screw or bolt for loctite, and also to ensure that all bolts are tightly fastened. But more so, it is wise to strip the pre-built parts down (head, tail, frame) and start from scratch. This way we can ensure a successful build. Hopefully Align will stop doing this (as it takes longer to take everything apart) and pack it in the same way as the 500+ helicopters in its range. But obviously purchasing a pre-built ready to fly package will mean all of this has been done for you.

The 450 Pro goes together very well, with very little deviation from the manual. To that point, the manual itself is very good, clear computer sketches of the build process. The manual also serves as a good reference for any adjustments the owner needs to do during the lifetime of the helicopter. It also covers the setup clearly of the ESC and gyro. Initially we start with the head. Again this is pre built mostly. But it is wise to go over each screw and make sure loctite has been applied and the screw is firmly tightened. The main points to consider at this stage are getting the flybar positioned correctly, so we have an equal amount of length on both sides of the head. Also, when screwing on the paddles, making sure that they are set to an equal distance as there counterpart on the opposite side. Otherwise vibrations may be evident leading to flight control issues. All of the control arms except for the upper mixers to swashplate are of fixed length and solid plastic. This removes any potential errors in measurements, and leads to a more accurate and pain free setup procedure later on.

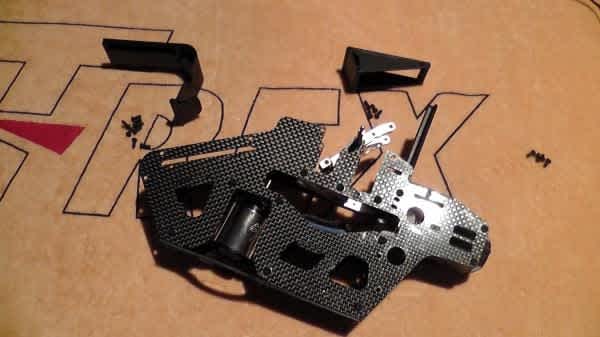

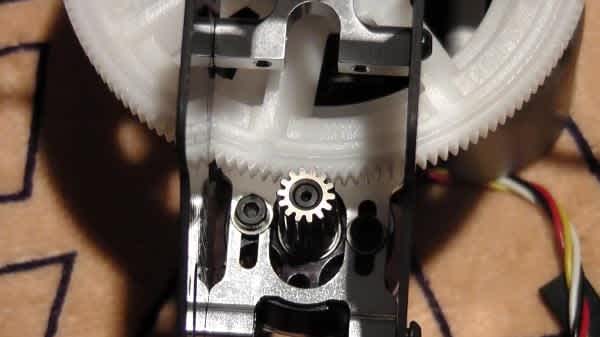

Next we construct the frame. Again, removing all the pre installed bolts, and re-building the frame. The next part is very tricky if unaware of the mechanics and order of the build. The servos are arranged in such a way that if you are leaving the frame built as it comes from the factory. It is necessary to remove some bolts from the CNC servo supports, pivot them, and slide into place the rear elevator cyclic servo. As Align have incorporated the servo mounts into the bearing blocks. Otherwise it’s impossible to get into place. Another point is we should install the motor before the servos, as it is almost impossible to access the motor bolts with the cyclic servos in place. We need to ensure the motor is in the rite position before securing. So at this stage we slide in the main shaft and attach the main gear. So we can line up the motor pinion with the main gear. Leaving a small gap between the teeth, so they don’t wear with the constant friction of close contact. Despite the tricky nature of this section, Align have done a good job in the design and construction of this section of the helicopter. Removing the front plastic battery holder also makes this part easier. The build is as expected much more involved than described, but described here are just some of the points that require a little extra care.

At this stage it is a good idea to do a large portion of the electronics install. As removing the frames bottom plate we have good access to the helicopters internals and we can route the cyclic servos to the front of the helicopter. Placing the ESC in the front of the helicopter under the battery tray. Installing the electronics at this point allows for a much neater installation as when the head, tail, and undercarriage is in place access can be tricky. It is always a good idea to power up the receiver, either with a receiver battery pack, or via the ESC (remembering to unplug the motor cables) and check for the centre position of the servos, cyclic and tail. The servo horns can then be fixed in place knowing that they are at the central 90 degree positions, it also allows us to bind the receiver before replacing the bottom plate of the frame and sealing away the electronics. As with a small heli like this we need to make the most of all the space we have, and it is very limited on space.

The Pro version of the 450 includes a torque tube drive. This makes the construction of the tail easier in some ways. As we don’t have to worry about tail belts. But we must make sure the correct installation of the torque tubes bearings, otherwise we may experience stripped gears or incorrect operation. In the simplest form, it is applying some CA glue to the central point on the torque tube, and then sliding on the bearing (without dust cover) and fixing the bearing to the centre. Being careful not to get any CA glue on the bearing itself as we don’t want to hinder its operation. Next we need to apply the rubber bearing seating/dust cover to the bearing. We then coat this in grease, and ease it into the tail boom, sliding it into position. The tail unit is checked for loctite and built as per the manual, it is then locked into place onto the torque tube. Remembering to slide on the pushrod guide rings before attaching the tail boom to the tail block on the main frame.

Now we have the tail in place and secure we can attach the head unit, sliding it into the bearing block and fixing the main gear in place with the supplied bolt. It should fit snug to the motor pinion, as we checked for this earlier. Also, as we checked for the servo centre positions, we can go ahead and attach the control rods from the swash to the servos. During the build we set them to the length given in the manual. This can be adjusted later whilst setting up the helicopter.

The gyro is placed in position at the top of the helicopter on the provided mounting platform by the swash guide. Mounting of the tail servo is straight forward, two of the screws supporting its mounting can be removed and it then pivots out to allow the servo to be screwed in place.

So with the build almost complete, the overall construction and quality of the components is exceptional. All parts go together well, and are of a high quality. A good tool set is essential, as using wrong size hex keys can strip the bolts. Now we just need to set up the helicopter, and then we can look at its flight characteristics.

Setup

Setting up this helicopter is very straightforward, the supplied blades are made of good quality carbon fibre, and the supplied set required no changes during balancing. With the suggested pushrod link lengths the swash is near perfect, requiring only minor adjustments to make it level. As mentioned before, due to the majority of the links being a fixed length, there is little room for error. Spinning the helicopter up and checking the blade tracking reveals an almost perfect track. Requiring just a turn of one of the pushrods in order to bring it into line. Remember, blade tracking is a very dangerous job, so always wear suitable eye protection. As mentioned before though, with any pre-built package all of these setup procedures will already be complete.

The T-Rex 450 Pro, once complete and mechanically setup requires some programming of the radio, and then it is ready for flight. Giving it a gentle pitch and throttle curve will result in a nice flying experience for the beginner. More aggressive curves will give a crisper 3D experience.

The ESC comes ready to fly from the factory with the default settings suitable for this model and for all round flight. To confirm, double checking the audible cues at start up before spooling up the model. It’s also worth noting that the audible beeps are only heard with the motor plugged in, as it generates the noise. The gyro is very easy to setup, requiring very little input except for setting the servo travel distances and making sure the direction is correct.

Conclusion

The Align T-Rex 450 Pro is quite rightly not a V3 of the original 450 design. It is a whole new beast. To that end Align have done a good job, producing a lovely little model, with much bigger aspirations. The quality of the build is excellent, and the helicopter performs excellent out of the box. That is literally the case, all that is needed is a receiver, transmitter and battery. The rest is supplied in the super combo.

Due to the new more powerful motor being used it has ample room for performance flight. A seasoned veteran would get just as much use for this as the beginner. The supplied Align GP750 Gyro and 35A speed controller are a good pairing, providing a reliable electronic basis. Pairing this with a Helicommand unit (as shown in the photos) can give the ultimate beginner platform, super stable and not requiring massive amounts of land to fly it in. The actual flight performance should be good, the 450 Pro was designed by Jason Krause, so it happily pumps out the power even at +/-15 degrees of pitch the head doesn’t get to bogged down and remains responsive. The value of the super combo deal is also very good value when comparing it to the costs of buying the items separately. All in all a superb all rounder, and sure to give hours of enjoyment. Keywords: Trex 450 Pro Trex 450 Pro Kit Trex 450 Pro Spares