Case Studies

Drones Save Balfour Beatty VINCI £5m On HS2 Project

Balfour Beatty VINCI will save £5m and improve safety by deploying drones during the construction of HS2 - Europe's largest infrastructure project. Upgrading to the DJI Mavic 3 Enterprise has helped BBV cut drone surveys by more than 50%,

Balfour Beatty VINCI (BBV) is deploying drones, including the DJI Mavic 3 Enterprise, on the HS2 development - Europe's largest infrastructure project;

BBV will save an estimated £5million over five years by deploying drones;

Drones are a more efficient solution: 10-20 minutes to measure a stockpile, compared to at least half-a-day using alternative methods;

Upgrading to the DJI Mavic 3 Enterprise, from the DJI Phantom 4 RTK, has helped BBV cut drone surveying times by more than 50%;

BBV achieving accuracies of 20-25mm, without GCPs - using Mavic 3 Enterprise;

Drones are a safer solution: BBV has removed 800 'working at risk' days by deploying drones;

heliguy™ has supported BBV's adoption of the Mavic 3 Enterprise on the HS2 development, including the delivery of survey-specific training.

Balfour Beatty VINCI (BBV) will save an estimated £5million by deploying drones on the HS2 development - Europe's largest infrastructure project.

And upgrading from the DJI Phantom 4 RTK to the new DJI Mavic 3 Enterprise has cut drone surveying times by more than 50% - taking BBV just 12 minutes to complete one survey, compared to 29 minutes, and a battery change, with the P4R.

The drone data is processed in Esri SiteScan to produce georeferenced, high-resolution interactive orthomosaics...

...and 3D models/meshes.

These datasets, enhanced by the Mavic 3 Enterprise's upgraded sensor, provide detailed site updates and enable streamlined volumetric calculations.

BBV is designing and building the northern stretch of HS2's first phase. Covering about 90km - from Long Itchington in Warwickshire, to the centre of Birmingham and on into Handsacre, in Staffordshire - it is the largest section of stage one.

The size, scale, and scope of the development pose logistical, financial, environmental and time-related challenges.

Drones help tackle these challenges by enabling BBV to track progress, measure stockpiles, and monitor earth movements more safely, efficiently, and cost-effectively than using traditional, manual methods.

For instance, operators can collect stockpile data in 10-20 minutes from a position of safety. By contrast, manual techniques take at least half-a-day to measure the same stockpile - with surveyors required to clamber over large quantities of material.

Accuracies of 20-25mm are being achieved with drone technology, without deploying ground control points (GCPs).

By digitising the project, the data can be centralised and viewed remotely: Cutting the number of site visits required - helping to reduce the development's carbon footprint - and facilitating site-wide communication for enhanced project management and collaboration.

Lee Johnson, Senior Survey Manager for BBV, said: "Drones allow us to cover large areas very efficiently and we can survey far more safely from a remote position, removing people from potentially dangerous areas. By deploying drones on the HS2 development, the cost-savings will be substantial: We estimate that over five years, drones will save us approximately £5million.

"Drones provide many benefits going across multiple departments: At the centre of this is the DJI Mavic 3 Enterprise - which collects the same reliable data in less amount of time. It is a game-changer."

heliguy™ has supported the integration of the DJI Mavic 3 Enterprise on the HS2 scheme, providing the hardware and delivering drone and survey-specific training to help BBV realise the potential of the technology.

HS2 is Britain's new high-speed rail line, bringing new levels of accessibility - connecting major cities, businesses, and 30million people, and reducing travel times.

The first phase, costing around £45Bn, will feature 134 miles of dedicated track between London and Birmingham. It is scheduled for completion between 2029 and 2033. Further phases are to follow, including West Midlands to Crewe, then on to Manchester.

Drones For Construction: More Efficient Surveying

Drones enable BBV to conduct more efficient aerial surveys.

When flying at a slow speed at 50m altitude, BBV can survey 1km of mainline in 45 to 60 minutes. Manual methods would take at least half a day.

This makes it easier for BBV to conduct more regular surveys, putting more up-to-date information in the hands of managers for enhanced oversight and decision-making.

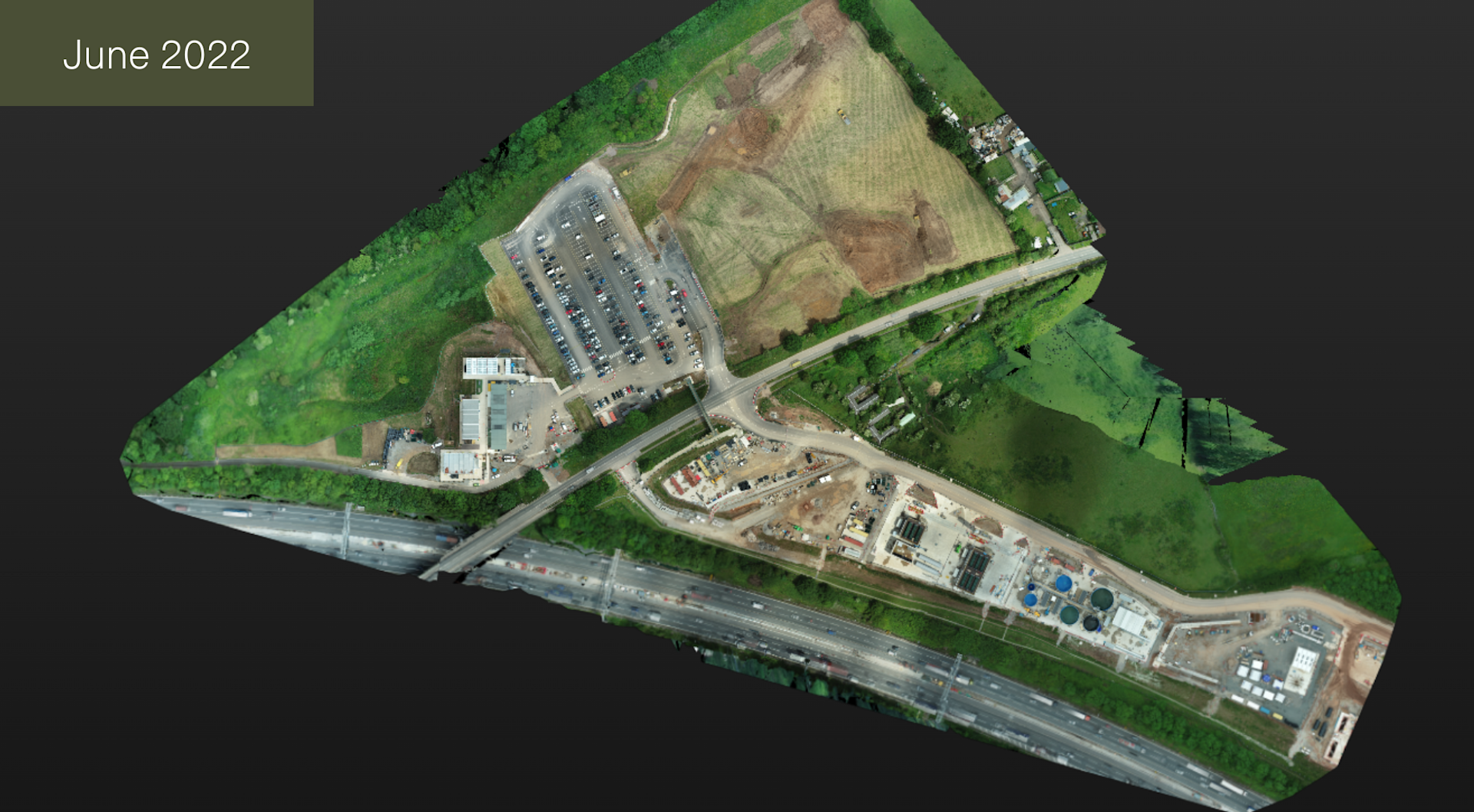

For instance, this side-by-side comparison shows how stockpiles have changed at BBV's Kingsbury compound over the course of a month.

Drone data provides the following benefits:

High-definition imagery and 3D terrain models for project monitoring, progress surveys, tracking vehicle and earth movements, and volumetric calculations;

Showing compliance with design tolerances in built structures against BIM and CAD models;

Speeding-up design cycles, particularly in earthworks and excavations.

Monitoring the installation of utilities;

Rapid and centralised data, shared with multiple stakeholders and various teams.

Indika Seneviratne, Project Surveyor at BBV, says: "The improved camera on the Mavic 3 Enterprise provides good quality images to create detailed orthomosaics which can be used by various departments, including engineers and designers."

Progress Reports

By deploying drones, BBV predicts it will save £20,000 a year on monthly progress surveys on a single site.

Regular progress reports help schemes stay on schedule, and enable teams to spot mistakes and identify issues earlier.

For instance, these two orthomosaics show how work to extend the Bromford Tunnel, from Birmingham into Warwickshire, has progressed over an eight-month period.

The Mavic 3 Enterprise's quality sensor - 4/3 CMOS, 20MP - helps to build detailed maps and models: Useful for zooming in to see sections of the site in more detail.

Lee said: "Regular site updates are required and drones are a much more safe and efficient way of collecting this data.

"The orthomosaics can be viewed remotely, reducing the need for office-based staff to visit the site in-person, which also helps to reduce the carbon footprint during the development."

Stockpile Monitoring

Regular aerial insights are also crucial for monitoring stockpiles and earth movements.

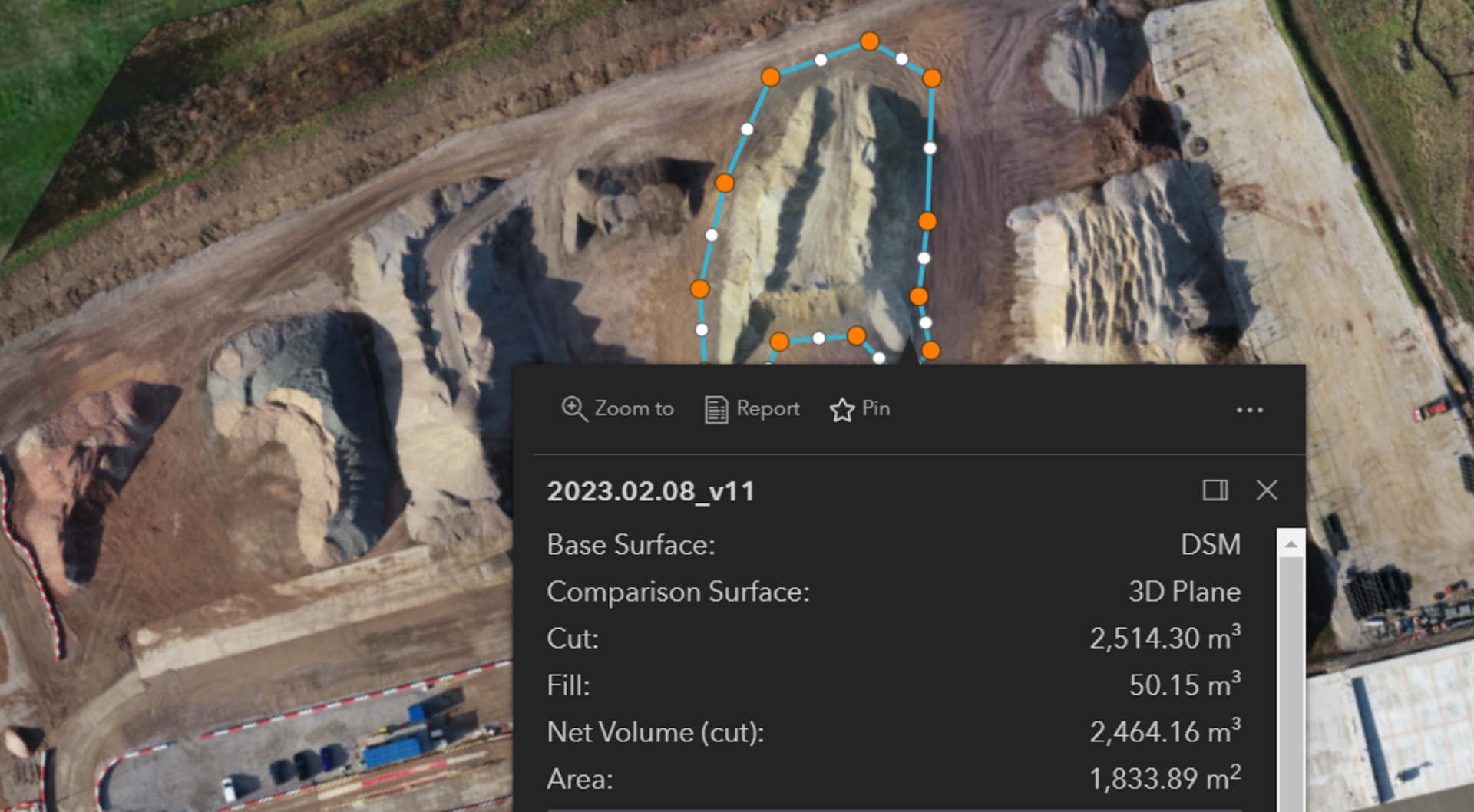

The drone data can then be fed into a data processing software - in this case Esri SiteScan - to provide insights on:

Size, length, height, and volume of a stockpile.

Changes to the stockpile, such as how much material has been added and removed.

The streamlined workflow is as follows:

1: After selecting the polygon tool, points are selected around the stockpile to manually choose the desired area to measure.

2: This provides detailed calculations about the stockpile, including the area and the net volume.

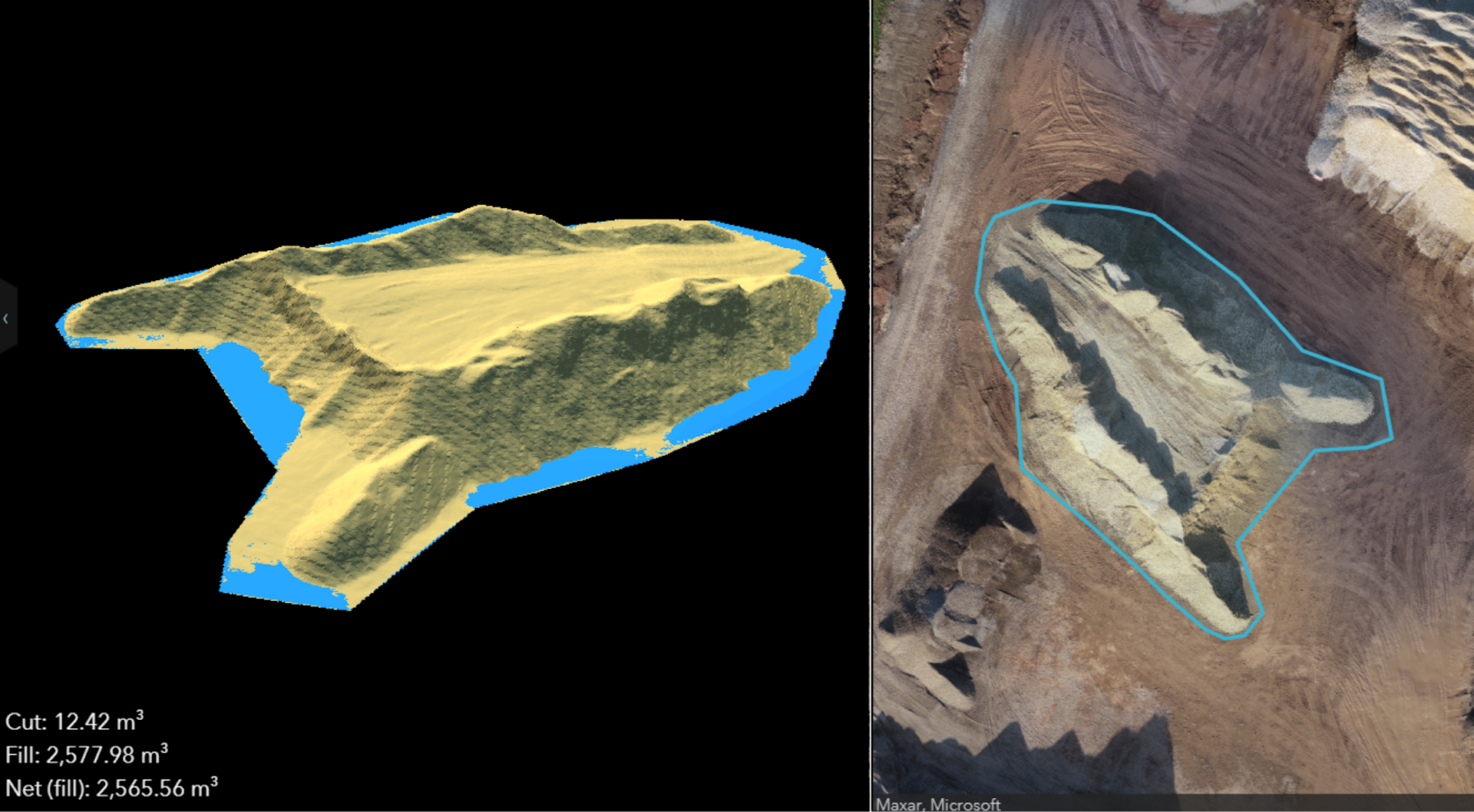

3: This image shows how the stockpile has changed over time, comparing its previous footprint (blue) to its new size (yellow).

These insights enable detailed forecasting, enhanced supply-chain logistics, and reduced write-offs.

Esri SiteScan enables BBV to manage an increasingly complex and varied use of drones and meet the needs of multiple teams, from logistics to site managers to engineers.

This centralised data is accessible throughout the lifecycle of the scheme.

DJI Mavic 3 Enterprise Cuts Drone Surveying Times By 50%

The DJI Mavic 3 Enterprise helps BBV collect accurate data in half the time compared to the P4 RTK, and it can fly for longer, covering larger areas in a single flight.

The table shows how fast the M3E conducted mapping missions within specific sections of BBV's Kingsbury compound - one of the most important hubs in the construction of HS2 Phase 1. The flights were conducted at a fast speed, at 80m altitude, to avoid tall objects including tower cranes and silos.

Location | Flight Time | Battery Remaining |

Ponds Area (Flight Distance: 4.8km Survey Area: 0.17km²) | • M3E: 8 mins • P4 RTK: 16 mins | • M3E: 71% • P4 RTK: 33% |

Office Area (Flight Distance: 9.3km Survey Area: 0.47km²) | • M3E: 12 mins • P4 RTK: 29 min | • M3E: 64% • P4 RTK: 20% & 56% (two flights required) |

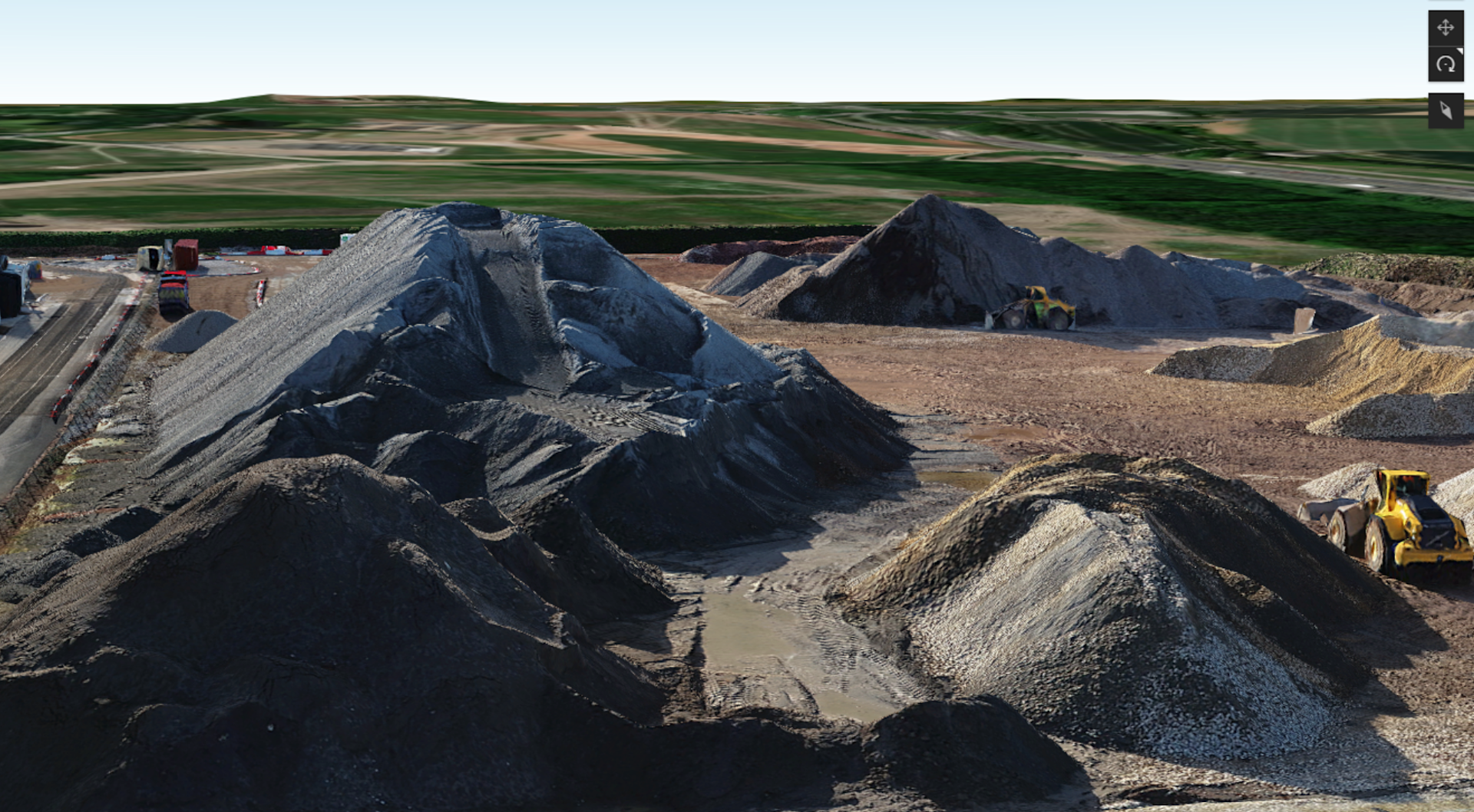

Used for stockpiling materials and producing concrete for railway infrastructure, the Kingsbury compound - pictured below - is the size of 74 football pitches. So, the M3E's ability to survey more efficiently - covering larger areas, more quickly - is essential.

The Mavic 3 Enterprise is a more efficient surveying drone compared to the Phantom 4 RTK because it has a longer battery life, larger sensor, and a more rapid interval shooting rate.

The Mavic 3E's larger pixel size and intelligent low-light mode offer improved performance in dim conditions - extending the window to conduct drone surveys.

The table below shows the key features which helps to make the Mavic 3 Enterprise more efficient than the Phantom 4 RTK.

Mavic 3 Enterprise | Phantom 4 RTK | |

Sensor | 4/3 CMOS; 20MP | 1 inch CMOS: 20MP |

Pixel Size | 3.3μm | 2.4μm |

Minimum Shooting Interval | 0.7 seconds | 2.5 seconds |

Maximum Battery Life | 45 mins; 42 mins with RTK Module | 30 mins |

Maximum Mapping Speed | 15 m/s | 13 m/s |

Lee said: "The Mavic 3E will be replacing our P4RTK fleet as it is a great drone, has strategic advantages, and is the obvious successor."

Read our DJI Mavic 3 Enterprise vs DJI Phantom 4 RTK blog for an in-depth comparison between the two drones.

Drones Enable Safer Data Collection

Drones are helping BBV collect data more safely.

BBV estimates it the removal of 800 'working at risk days' and a cost-saving of £30,000 a year by using drones to better monitor aggregate stockpiles.

Manually inspecting stockpiles involves clambering over large quantities of material that is potentially unsafe underfoot. Some HS2 stockpiles can be 10 metres high!

This 3D mesh, taken from drone data captured at the Kingsbury compound, shows the size of some of these stockpiles.

Rather than clambering over these piles, drones can be deployed to collect the data from a remote and safe position.

Drones also help to reduce People Plant Interface - one of the top fatal risks in the construction industry, which includes workers being struck by moving vehicles.

Deploying drones dramatically reduces this risk by removing the need for staff to be walking around site collecting data.

Previously, some surveys were excluded from being too close to plant, or surveys were conducted when the plant was not operational, resulting in downtime. Drones eliminate these issues.

DJI Mavic 3 Enterprise: Enhancing Drone Safety

To further improve on-site safety, the Mavic 3 Enterprise is one of DJI's safest drones to date - with enhanced features compared to the Phantom 4 RTK.

For instance, the DJI Mavic 3 Enterprise has state-of-the-art obstacle sensing and navigation systems.

This includes DJI's new Advanced Pilot Assistance System (APAS 5.0), which combines data from six vision sensors and two wide-angle sensors to detect obstacles in all directions - particularly useful for navigating around the HS2 site, which features infrastructure such as cranes and silos.

In terms of connectivity, the M3E features DJI’s latest image transmission technology (Quad-antenna O3 Enterprise Transmission) which enables a more stable link between pilot and aircraft in complex environments.

Mavic 3 Enterprise | Phantom 4 RTK | |

Obstacle Avoidance | * Omnidirectional binocular vision system; * Infrared sensor at bottom of aircraft | * Forward/Rear/Downward binocular vision system; * Infrared sensors at two sides |

Advanced Return To Home (Plans and initiates the most efficient, hassle-free return journey possible) | Yes | No |

APAS 5.0 | Yes | No |

DJI AirSense (ADS-B technology to warn of nearby manned aviation) | Yes | No |

Transmission | DJI O3 Enterprise Transmission 8km max transmission distance (CE) | DJI OcuSync Transmission 5km max transmission distance (CE) |

To further enhance safety, the Mavic 3 Enterprise is a smaller, lighter drone than the Phantom 4 RTK.

This reduced footprint, coupled with the Mavic 3's ability to be folded, also makes it a more convenient and portable solution to carry around site.

Lee said: "The Mavic 3E is a smaller drone, making it easier to transport, and quickly deployable."

The table below shows the comparison between the Mavic 3 Enterprise and Phantom 4 RTK.

Mavic 3 Enterprise | Phantom 4 RTK | |

Weight | 935g (inc RTK Module); Max Take-off: 1,050g | 1,391g |

Foldable | Yes | No |

Propellers | Integrated with aircraft, detachable | Needs to be installed every time |

Accurate Data Collection With Drones

Drone data maybe safe and efficient - but it is also accurate.

BBV is achieving accuracies of 20-25mm with drone technology, without deploying ground control points (GCPs).

In one survey, BBV achieved an average absolute deviation of 0.019 (19mm) in elevation averaged out across 665 points (including seven anomolies).

Average of 665 points | Difference |

0.019 | |

Standard Deviation | 0.015 |

Max | 0.073 |

Min | -0.059 |

Mode | 0.029 |

Summary: Drones Benefiting BBV's Construction On HS2

BBV's digitised workflows are transforming surveying practices, introducing new levels of efficiency, accuracy, and safety. On major projects, such as HS2, the ROI is significant.

Deploying drones helps BBV with:

Quality Assurances

Health and safety

Planning and project control

Commercial and quantity surveying

Design and construction management

Reduced environmental impact

Lee said: "Drones are highly-valuable for surveyors: While they won't replace traditional survey techniques, they are a complementary solution and are revolutionising the construction industry, helping to combat logistics and the sheer size of sites, like HS2.

"Before we had the drone programme, surveys were conducted very traditionally - boots on the ground, walking over the land. Since deploying the BBV drone programme, we are finding many benefits going across multiple departments.

"The cost-savings are substantial, we're reducing surveying manhours, which in turn reduces our carbon footprint, while the collaborative, real-time nature of drone data improves visibility, communication, and decision-making."

Contact heliguy™ to start or scale your AEC drone programme, including adding the Mavic 3 Enterprise to your workflows and taking industry-specific AEC drone survey training.