Case Studies

Determining ROI Of DJI Dock For Utilities Inspections

DJI Dock can revolutionise the utility sector. Find out how this drone in a box increases efficiency and ROI for solar panel inspections, and how teams are conducting automated and remote power grid operations to replace manual inspections ... Read More

DJI Dock is a transformative solution for the utilities sector - automating flights and facilitating remote monitoring;

Scenario test shows that DJI Dock can more than double annual ROI, compared to conducting manual solar panel inspections;

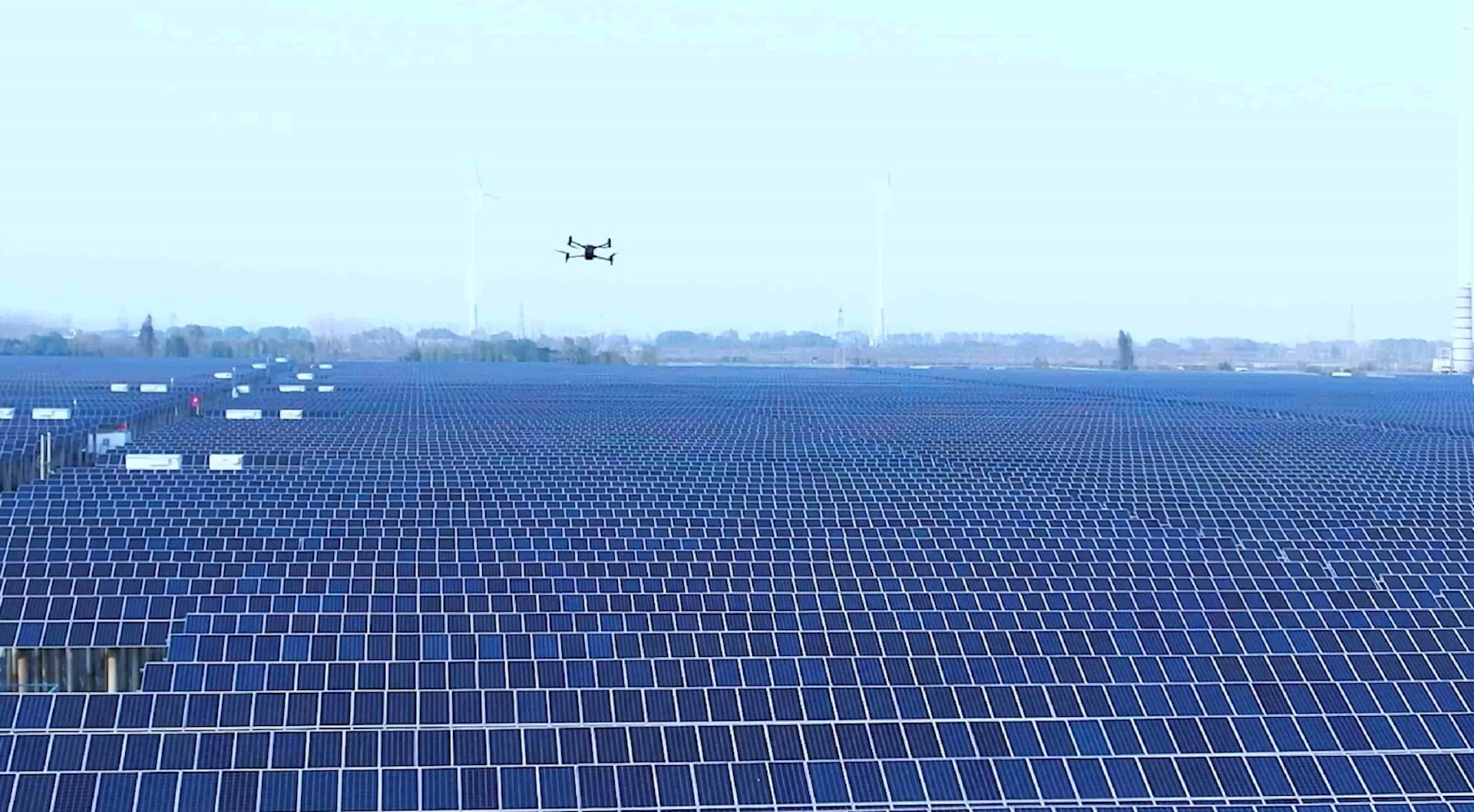

Frequent checks are essential for maintaining energy output: On a 100MW solar farm, efficiency of DJI Dock enables quick and regular checks, whereas manual methods could take up to 65 days to inspect the site once;

In China, automated and remote flights from the DJI Dock are helping one power company inspect a substation 60km away from the operations centre - saving staff from manually collecting data in temperatures as low as -20°C;

heliguy™ is a DJI Dock partner and will help organisations integrate this drone in a box into their workflows, including installation, training, and lifetime support.

The DJI Dock can revolutionise the utilities industry - increasing the efficiency of inspections and significantly improving return on investment.

In a presentation, Freda Peng, Global Solutions Engineering Director of DJI Enterprise, demonstrated the benefits of using the Dock for solar-panel and power-grid operations.

Deploying DJI's drone-in-a-box system would enable at least 12 inspections a year on a 100MW solar farm, compared to just two inspections annually using time-consuming manual methods - and with cost-savings more than doubled, she said.

And, in China, automating operations with the DJI Dock is helping remotely-located personnel collect data from substation sites 60km away - preventing staff from having to conduct manual inspections in temperatures of -20°C.

Elsewhere, teams involved in North America's first solar-farm inspection with the DJI Dock have described the technology as the future of solar site inspections.

heliguy™ is a DJI Dock partner and will help organisations integrate the Dock into their workflows, including installation, training, and lifetime support.

This blog explores how the DJI Dock can help the utilities sector.

DJI Dock For Solar Inspections

Drones are increasingly being used in the solar sector to aid every stage of a plant's life cycle, from planning to maintenance - helping to collect data quickly, efficiently, and safely. Read our Drones for solar panel inspections blog for more details.

But the drone-in-a-box revolution is ushering in a new era of automatic and easily repeatable inspections, further elevating UAS solar-panel inspections.

Especially suited to inspection missions, the DJI Dock's M30 Series drone has a powerful camera array to collect rich solar-panel data, such as its 12MP wide (visual) camera, and 48MP zoom camera with 200x max hybrid zoom.

Meanwhile, the M30T (Dock version) also features a 640 x 512 thermal camera, which can detect issues such as hotspots in cells, panels, or strings.

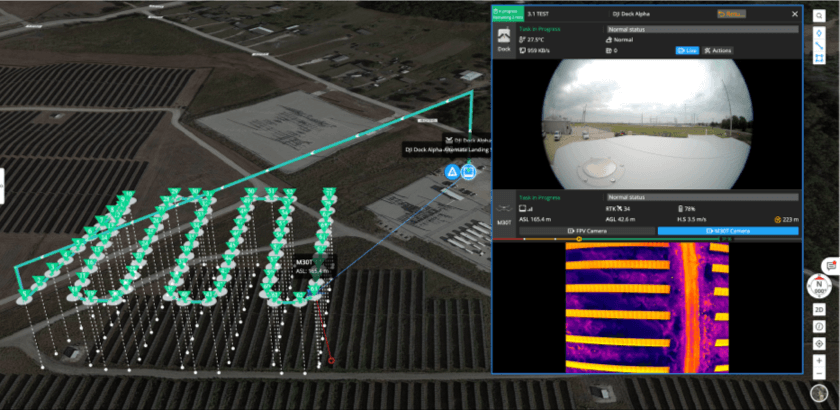

Missions can be planned and scheduled, and data centralised, using software such as DJI FlightHub 2, or third-party solutions such as FlytNow.

The potential for increasing ROI within the solar industry was demonstrated during a scenario test by DJI - showing how the Dock can be more beneficial compared to manual inspections, and conducting no inspections at all, for monitoring a solar asset to maximise on-site energy production.

The data was based on a 100MW farm.

Option 1: No Inspections

Doing no inspections at all could result in reduced power generation, which could end up costing up to 140K USD per year (equivalent to around £113,575).

This is because undetected faults or damages could cause equipment failure or even safety hazards.

Scenario 2: Manual Inspections

Manual inspections (service team walking around the site) could take two people five hours to inspect 1MW. This would take roughly 65 days to cover the whole 100MW site.

And many solar farm businesses like to inspect their site twice a year - which could result in an estimated annual cost of around 120K USD (equivalent to around £97,350).

Moreover, manual inspections can be prone to human error - and money could be lost due to issues happening between the two inspections.

Scenario 3: Automated Drone-in-a-Box-based Inspections

DJI Dock hardware and deployment, plus a third-party operations and analysis software, would cost around 45K USD (equivalent to around £36,500).

While this may seem like a significant investment upfront, it does provide long-term benefits in terms of increased efficiency, accuracy, and safety.

For instance, using a drone in a box can help teams inspect the site at least 12 times a year.

This means that the system can provide regular and timely feedback on the status of the solar PV system, allowing for proactive measures to be taken.

Case Study: SNEGrid Benefit From DJI Dock

One of DJI's solution partners, SNEGrid, in China, is able to process drone imagery with AI analysis and create reports.

This not only saves time and effort but also enables predictive maintenance and optimised performance.

SNEGrid is also working on a solution to integrate a DJI Dock with their inverter system, so whenever the inverter senses an error, the drone will fly to the corresponding location and inspect nearby panels.

Freda said: "This is another good example for how drone autonomy can be one piece of the IOT (Internet of Things) network and create a synergy with other smart devices."

For example, the data collected by drones can be integrated with weather forecasts, energy demand forecasts, and other relevant information to optimise the overall energy management system.

This would enable real-time monitoring and control of the solar PV system, as well as seamless communication among different components.

First DJI Dock Solar Farm Inspection Conducted in North America

Enel Green Power, a multinational provider of electricity and gas, has conducted the first utility-scale solar farm inspection in North America with the DJI Dock.

The landmark inspection took place at a 181 MWdc solar site in Texas, demonstrating the Dock’s ability to facilitate inspections on a utility-scale site.

William Badnaruk, the Head of Industrial Risk and Cross Technology Improvement at Enel North America, said: "We believe this technology is the future of solar site inspections because it enables us to discover issues and inefficiencies more quickly, which will ultimately reduce our operating expenses and improve production at a faster rate.”

This image shows the DJI Dock control interface through DJI FlightHub 2 - including thermal insights collected with the M30T's thermal sensor and the flight path the drone took.

Drone-in-a-box inspections allow for quicker identification and remediation of equipment-driven underperformance, which was found to have cost the solar industry billions of pounds in lost revenue in 2022.

Expediting inspections and repairs reduces safety hazards and fire risks, lowers costs for utilities and asset owners, and boosts revenue.

And, with automated, AI-directed drone flights, drone-in-a-box technology ensures power production is attained to its full potential – eliminating waste in the energy value chain, ensuring a more reliable flow of clean renewable energy, and ultimately furthering American energy security.

Grant Hosticka, DJI’s Head of Enterprise Solutions Engineering, North America, said: "There are a lot of operational considerations, such as pilot access to the site, data offload, and on-site flight planning, that are simplified with the DJI Dock.

"It automates operations and allows for repeatable methods of data collection, which we believe will change the face of solar inspections.”

Raptor Maps, a leading provider of solar asset management software solutions, built the necessary mission planning software to direct the M30T drone to conduct the inspection.

Power Grid Inspections With DJI Dock - A Case Study

DJI Dock also has the potential to revolutionise power grid inspections.

In Jilin, a city in northeastern China, powerline inspection crews from Jilin National Grid are responsible for restoring power after snowstorms.

However, with a winter that lasts six months and temperatures plummeting to -20°C, the crews are susceptible to frostbite and snow blindness, which poses significant risks to their safety and effectiveness.

To address these challenges, the DJI Dock has been deployed to conduct inspections that are too hazardous for human workers.

With just a few clicks, an operator at the operations and maintenance centre, located 60 km away from the Dock, can remotely select a Dock device and conduct immediate inspections of substations and connecting lines.

DJI Dock For Utilities Inspections: Summary

With its ability to conduct automated, scheduled, and remote operations, the DJI Dock can significantly benefit the utilities sector.

While these types of operations are currently limited in the UK - due to BVLOS development being at an adolescent stage - ROI scenario tests and existing case studies from around do show the potential of the DJI Dock.

And there is still an opportunity (in the UK) for organisations to begin to integrate the Dock into their workflows - flying in a VLOS capacity and utilising the software and the benefits of the Dock's drone - with a view to achieving BVLOS operations in the future to unlock the true potential of this drone-in-a-box solution.

To discuss the DJI Dock, associated software, training (including OSCs and BVLOS pathways) and integration, contact us.