Case Studies

Aureos Doubles Efficiency Using Drones for Powerline Inspections

Aureos uses DJI drones to double inspection efficiency, cut emissions, and collect thermal data.

The DJI M300 RTK and its cameras have transformed utilities inspection for UK engineering and construction specialist, Aureos;

See datasets showcasing the H20T's incredible zoom, thermal and automated inspection solutions, as well as LiDAR and photogrammetry models processed by DJI Terra;

The drone has doubled the efficiency of condition-based inspections and reduced carbon emissions by almost 50%;

Drones have enabled Aureos to conduct electricity inspections without shutting down critical infrastructure - expanding its client portfolio in the process;

Drone mapping has enhanced mission planning, combatted challenges faced with traditional methods, and streamlined team-wide communication;

DJI surveying ecosystem of M300 RTK, L1 LiDAR/P1 Photogrammetry sensors, and Terra mapping software build 'highly detailed and accurate' models.

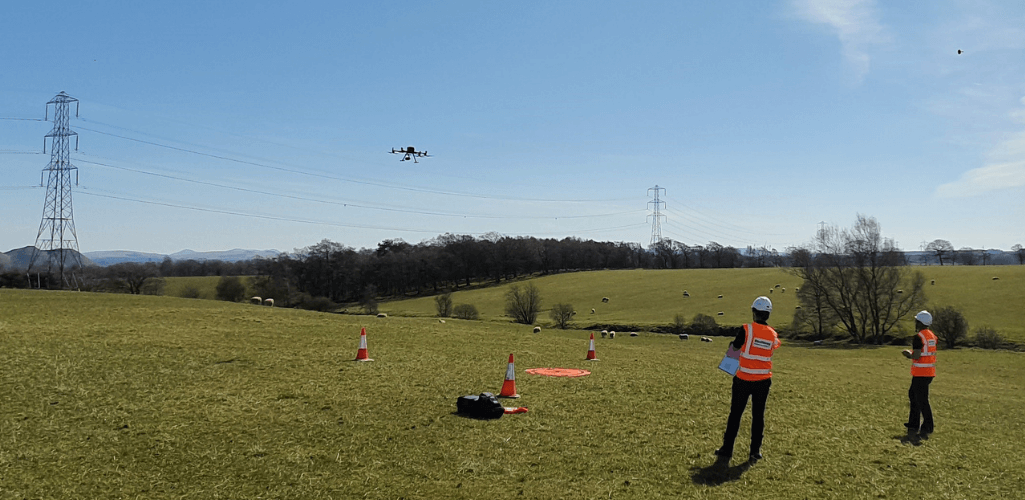

A leading specialist engineering business and provider of overhead powerline and substation services is using drones to double inspection efficiency and cut carbon emissions by almost 50%.

Aureos has invested in the DJI M300 RTK platform and its ecosystem of powerful cameras to collect better quality data, quicker and safer than before.

This video shows how the powerful zoom on the H20T camera helps Aureos capture crystal-clear imagery of critical infrastructure from afar - digitising condition assessments while removing the need for staff to work at height and eliminating asset downtime.

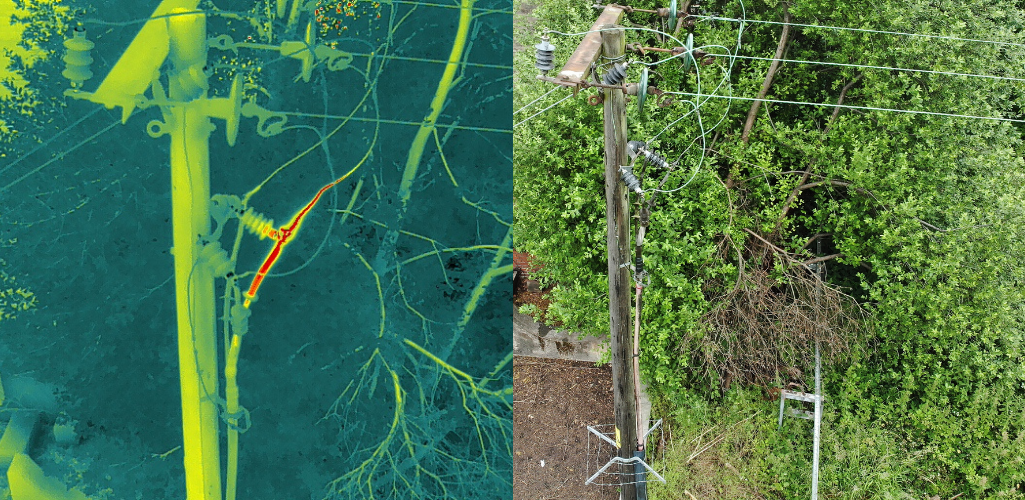

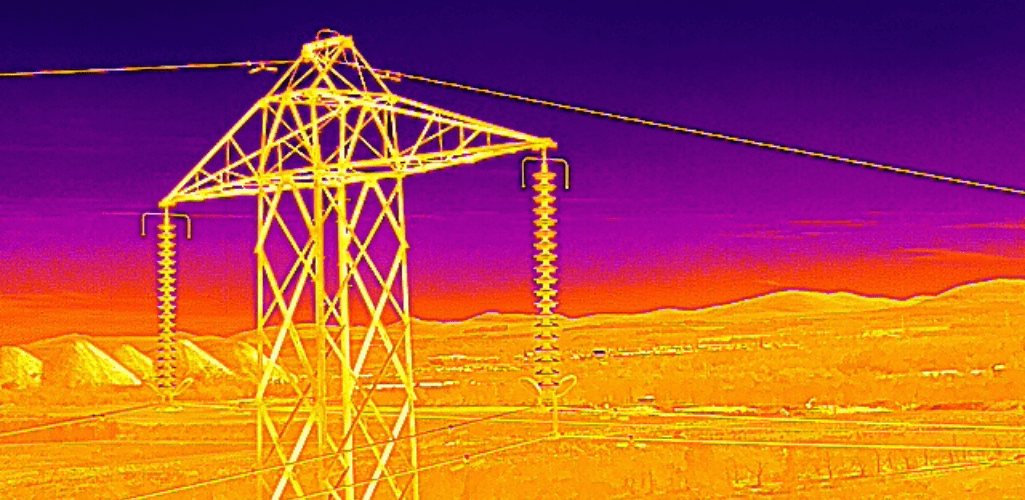

Meanwhile, the thermal camera of the H20T enables the team to spot defects or heat abnormalities. The picture below shows how the sensor identified an overheating cable joint (left image); a defect not visible during the visual inspection (right image).

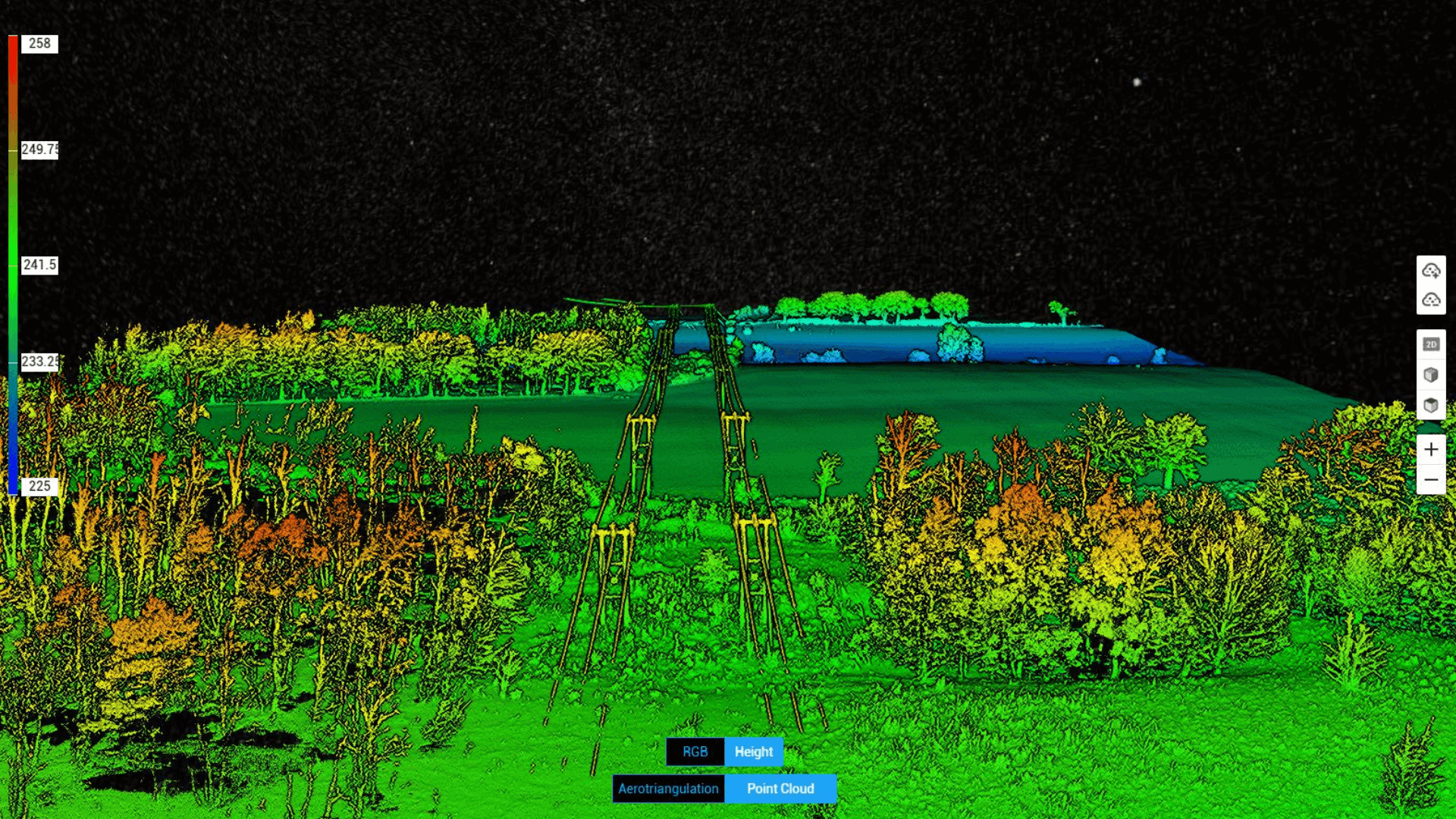

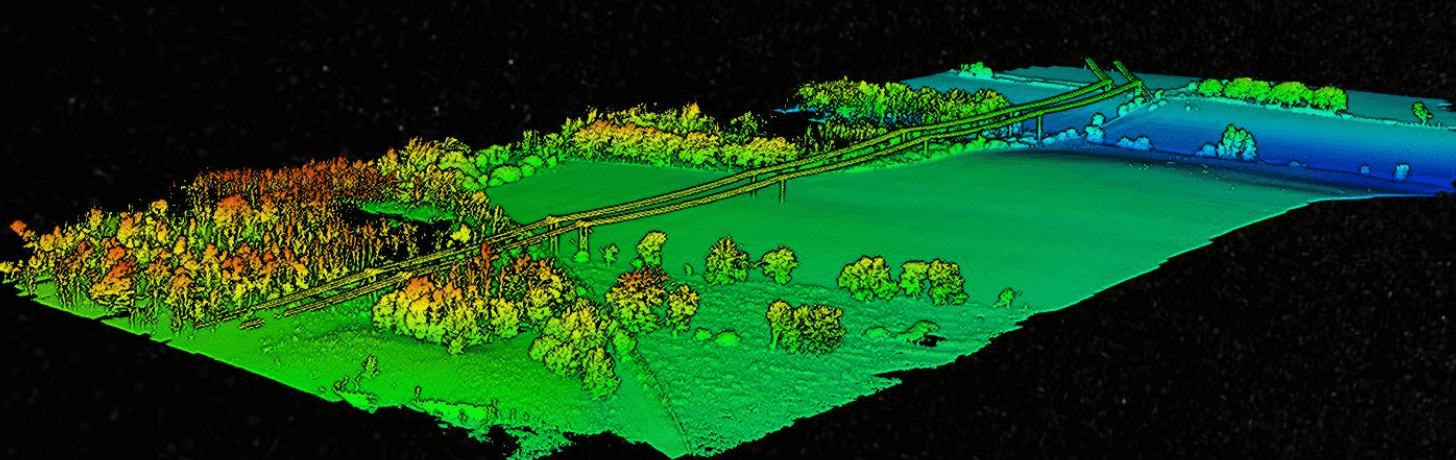

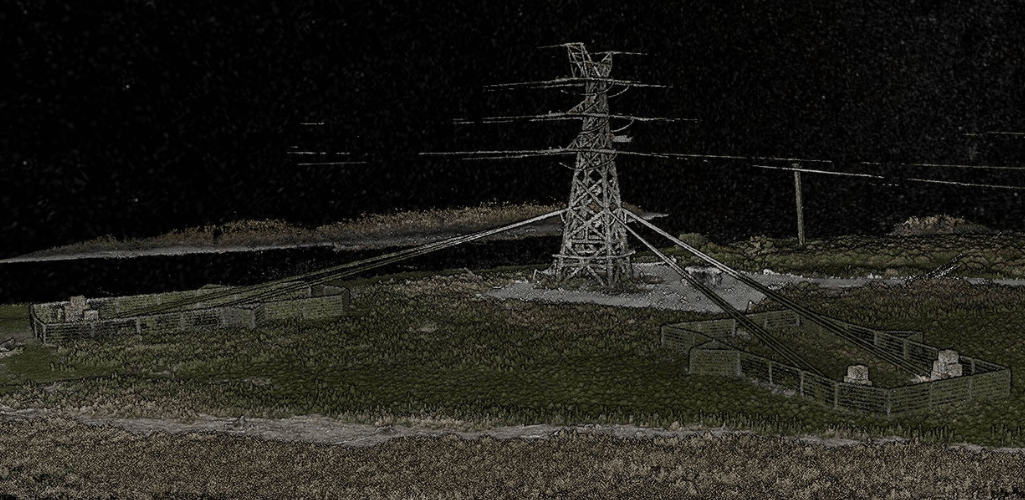

Aureos is also utilising drone surveying, deploying the P1 photogrammetry camera and L1 LiDAR sensor - in conjunction with DJI Terra - to build highly-detailed maps, models and point clouds to enhance mission planning and tackle challenges associated with traditional methods of powerline construction.

Aureos turned to the UK’s leading drone supplier, heliguy™, to adopt the technology, which is proving an effective tool.

Gordon Cranston, Project Construction Manager at Aureos, said: “Innovation is at the forefront of our business and drones are the future, bringing so many benefits to our operations and enabling us to gain competitive edge.

“Through a relatively small investment, drones provide an efficient and effective way of understanding the remaining lifespan of aging assets and determining investment programmes. They also reduce business risks and costs, enable us to access and develop new market places, and increase overall safety within high-risk environments which naturally drives efficiency during projects."

Drones For Utilities Inspection: Doubling The Efficiency Of Condition Based Assessments

The DJI M300 RTK and H20T sensor have revolutionised the way that Aureos conducts condition-based assessments, replacing a once time-consuming, labour-intensive and high-risk process with a quick, safe, data-rich and digitised alternative.

Traditionally, Aureos could inspect three electricity towers in a day, but the M300 RTK now helps the team inspect 6 per day - doubling the efficiency and cutting inspection costs.

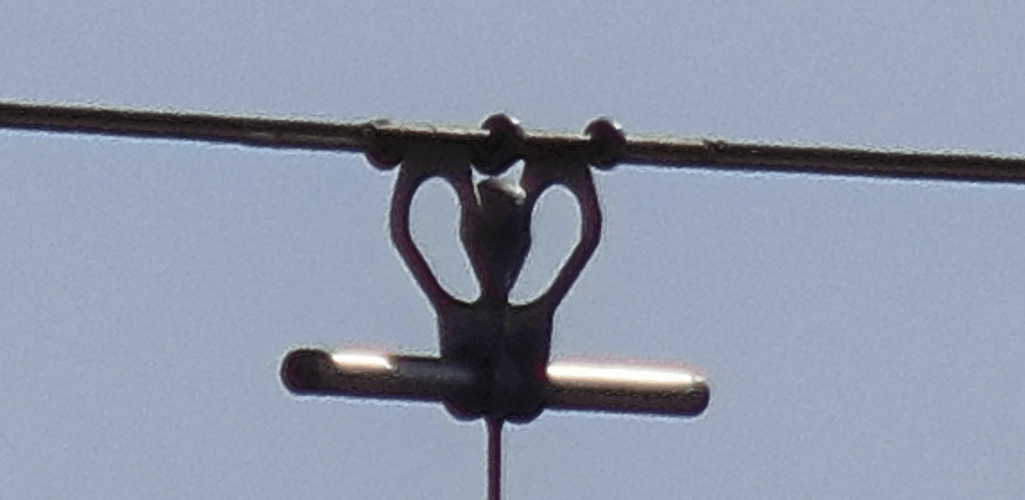

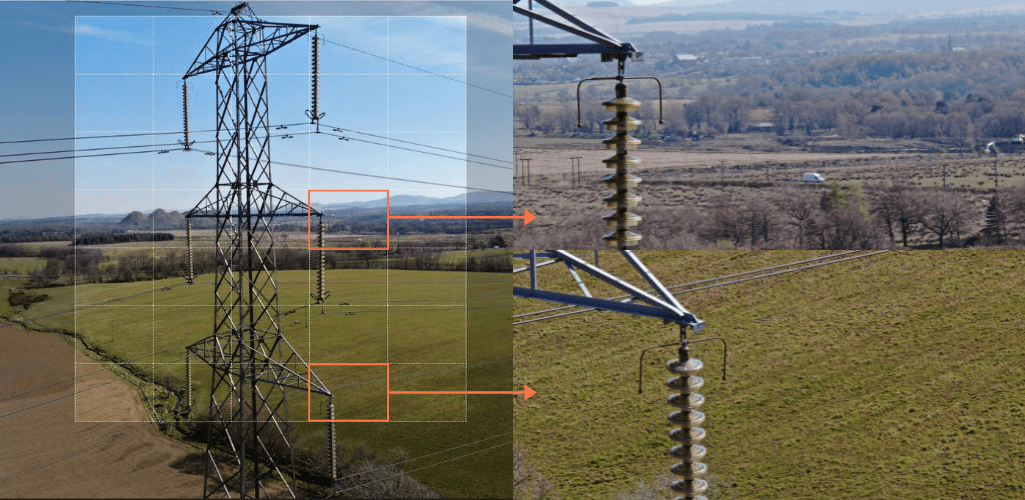

The H20T has a 23× hybrid optical zoom and 200× max zoom - and these next two images show just how effective this can be for inspecting critical infrastructure from afar.

The first picture shows an up-close view of a detuning spacer...

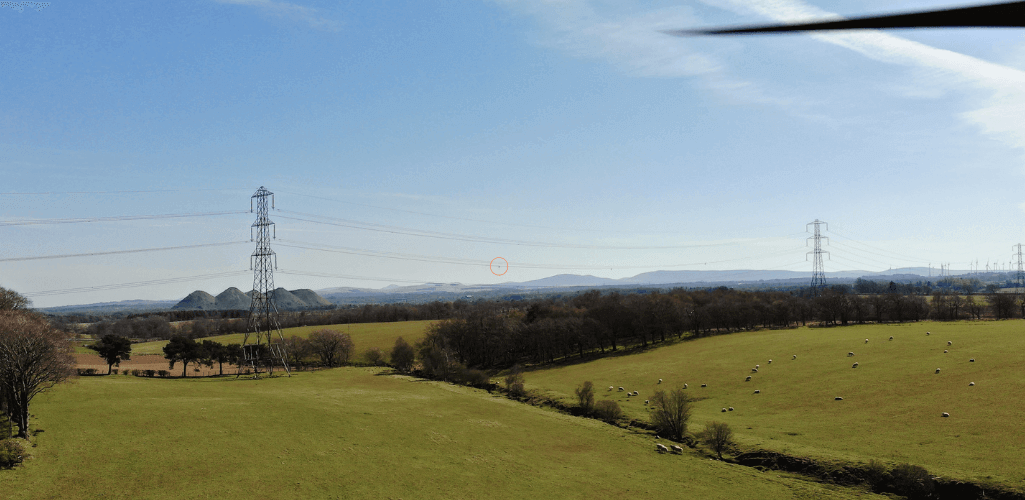

...which was captured by the drone 260 metres away! The detuning spacer is identified in this picture by the orange circle!

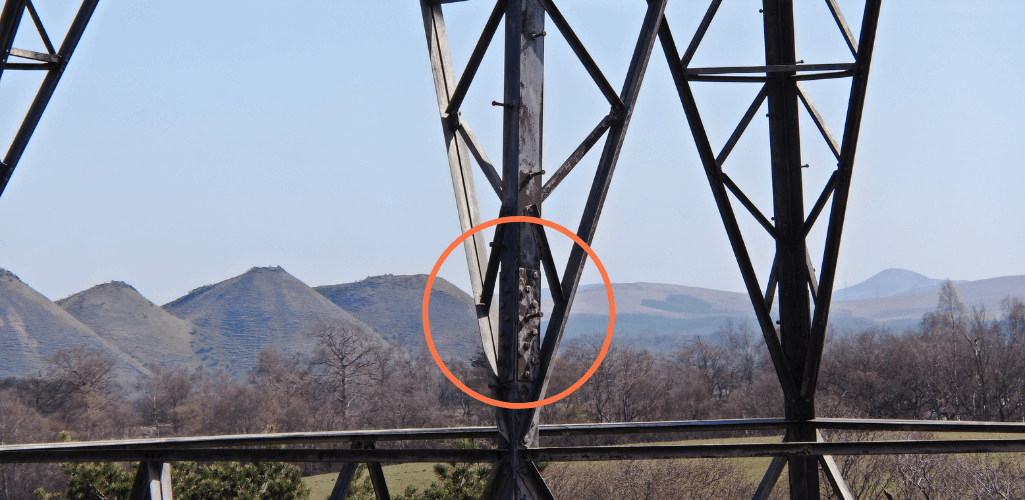

The level and clarity of the zoom removes the need to deploy costly all-terrain vehicles - such as an argocat - and stops staff having to work at height or clamber over difficult terrain. It also helps to identify rust, tiny defects or loosening bolts in great detail, as these series of images show.

The camera also enables Aureos to collect thermal imagery, enabling the team to spot defects or issues to help prevent fires that can occur as a result of failures in powerlines.

And all of this can be done while keeping the asset live: Something which has enabled Aureos to expand its client portfolio.

Gordon said: “We were asked by a major client to inspect a series of towers, on the proviso that they couldn’t be switched off. Typically, we wouldn’t have been able to do this, as we would have needed to turn off the power to keep our team safe while they were conducting the inspection - at height.

"However, the drone enabled us to inspect the network from afar, without boots on the ground and keeping the electricity supply live, which meant we could carry out this project for the client.”

As an added bonus, the company only needs to send a two-person crew – drone pilot and camera operator – to ensure optimal findings from each inspection. The high-resolution data can then be viewed back at the office and a strategic plan for asset maintenance and repairs can be produced.

In addition to cost and time savings, drone inspections have also enabled Aureos to cut its carbon emissions by 45.46%. The table below shows the difference between traditional inspection and drone-based assessment.

Equipment | Total Carbon Emissions (kgC)2e/per tower) | |

Traditional Methods | Vans x 2 4x4 x 1 Argocat x 1 | 62.6, including 19.5 from the argocat. |

M300 RTK Drone Inspection | 4x4 x 2 Drone x 1 | 34.2, including 0.04 from the drone. |

Automated Drone Inspections

The M300 RTK and H20T have smart features to enable automated inspection missions, enabling repeatable and highly-accurate data collection.

For instance, Aureos is benefiting from the High-Res Grid Photo function, which frames an area of interest in wide camera view before the zoom camera automatically captures a set of 20MP images of the area. These images are stored together with an overview image that can be viewed in greater detail, helping to facilitate precise and highly-detailed inspection.

In the below example, it took Aureos just 60 seconds to create this composite image of a pylon - consisting of 35 individual high-res grid images...

...and managed to use the high-res data to spot this damaged earth braid.

The H20T also has the AI Spot-Check function, which allows the drone to replicate the position, angle, and framing of interest areas for future missions.

This essential tool automates missions and collects thorough and repeatable data on each flight; particularly useful for regular inspections of the same asset.

Gordon said: “For all of these reasons, using the drone with H20T camera is highly advantageous for condition-based assessments.

“A big advantage of the H20T payload is that it has multiple cameras in one lightweight payload, including thermal, zoom, and wide-angle. It really is the complete package.

“This increases efficiency, and enables you to switch between wide-angle - for an overall view of an asset - and then home in on a specific part of the asset with the high-resolution zoom, before going back out again.”

Drone Surveying For Powerline Inspection

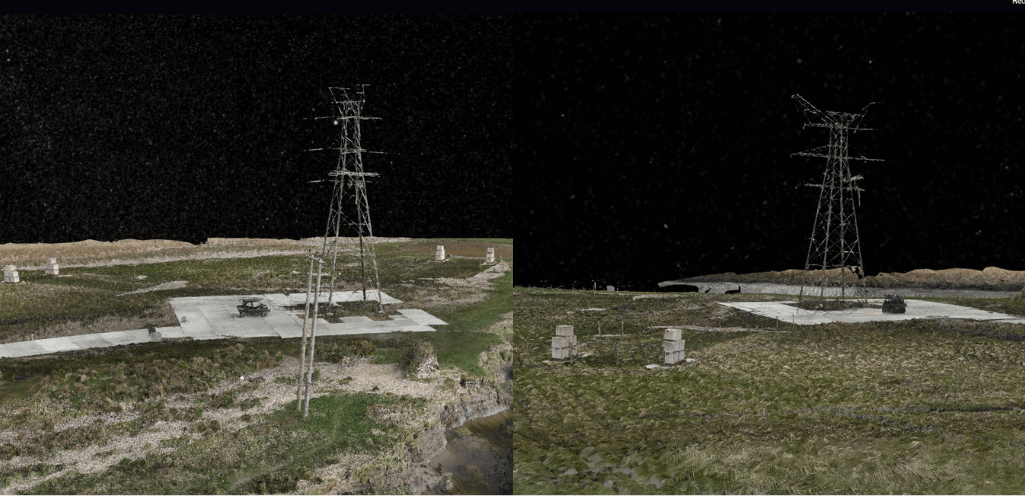

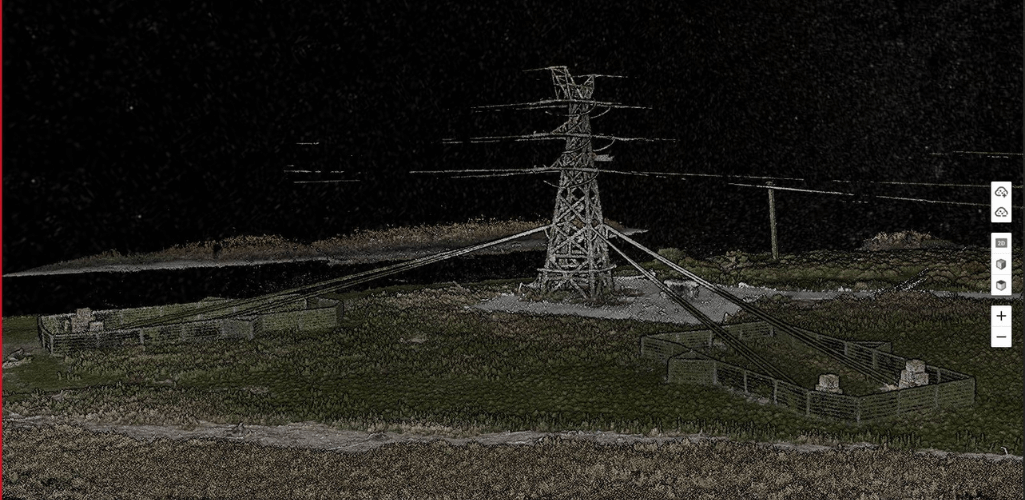

Aureos is using drone surveying techniques - such as photogrammetry and LiDAR - for advanced mission planning, to create highly-detailed, centimetre-accurate 3D models and point clouds.

Photogrammetry For Powerline Inspection

Aureos is deploying the 45MP P1 photogrammetry camera, in conjunction with the DJI Terra software package, to build these 'highly-accurate and highly-detailed' georeferenced virtual site maps and models.

These can be used to obtain deeper understanding of terrain, slopes, gradients and assets of an inspection area to help with pre-flight planning and operational requirements.

This information can also provide great insight into potential project risks such as access routing issues, water management (runoff), and early identification of environmental constraints.

These maps and models are highly-visual assets which can be shared with key stakeholders, subcontractors and clients, ensuring planning, coordination and even project progress is efficiently managed.

Gordon said: “This is vitally important for helping us plan a project. The drone is also valuable when trying to plan for a project in difficult-to-access areas.

"For instance, one of our schemes involved accessing a hill with a 1 in 5 gradient, which is very steep. Traditionally, staff would have been given a handheld camera and would have to navigate difficult terrain; the drone changes all of that.”

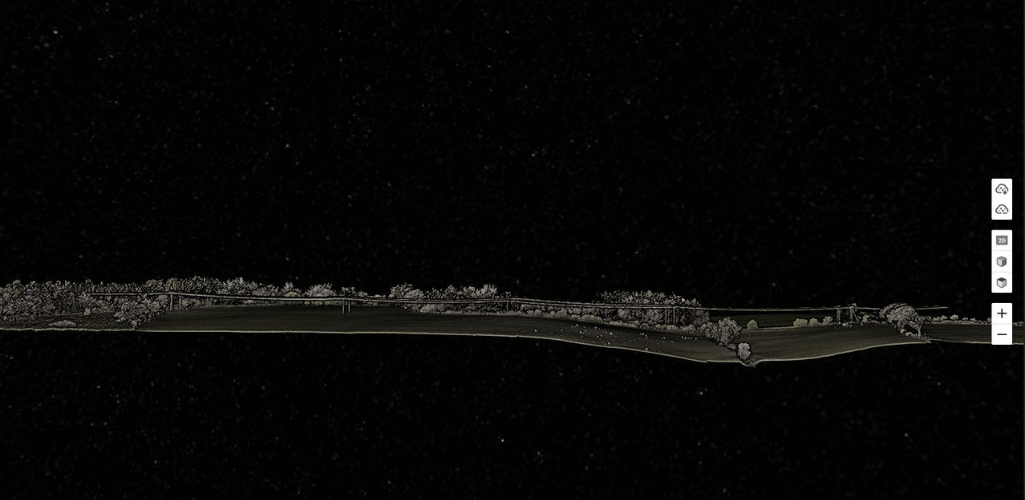

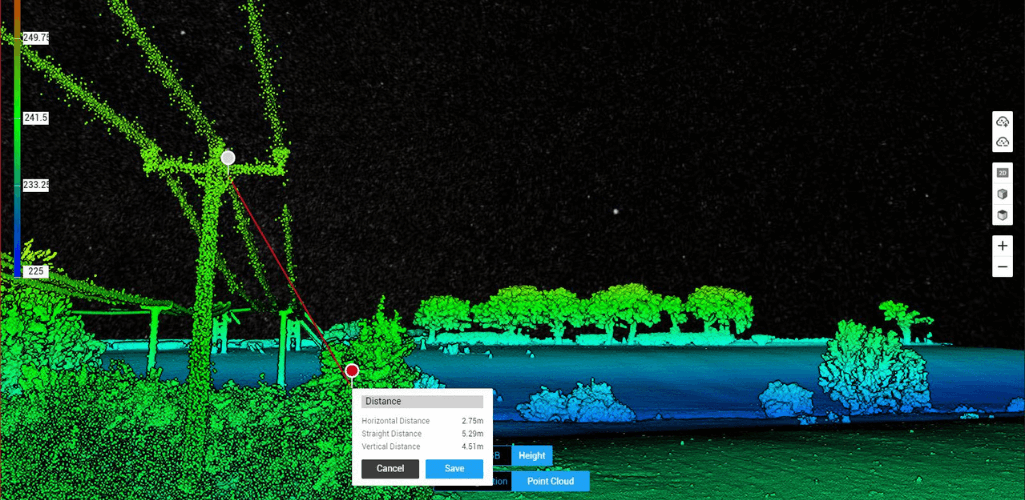

Drone LiDAR For Powerline Inspection

LiDAR models are key to overhead line construction and maintained projects, but traditionally, this technology has been expensive to acquire.

However, DJI’s L1 LiDAR sensor, engineered for the M300 RTK, is a more accessible, cost-effective solution, which delivers a powerful performance.

The L1 is able to generate true-color point cloud models in real-time, acquire 2km² of point cloud data in a single flight, supports up to 3 returns, and has a 1-inch visible light sensor for photogrammetry missions.

Aureos is utilsing drone LiDAR to combat traditional challenges associated with powerline construction planning.

These challenges include:

Lack of precise position data which makes it difficult to align BIM designs, road vector maps, and satellite imagery; all of which costs time and labour.

The BIM designs can be quite different from the reality model, making it difficult to visualize and verify the design.

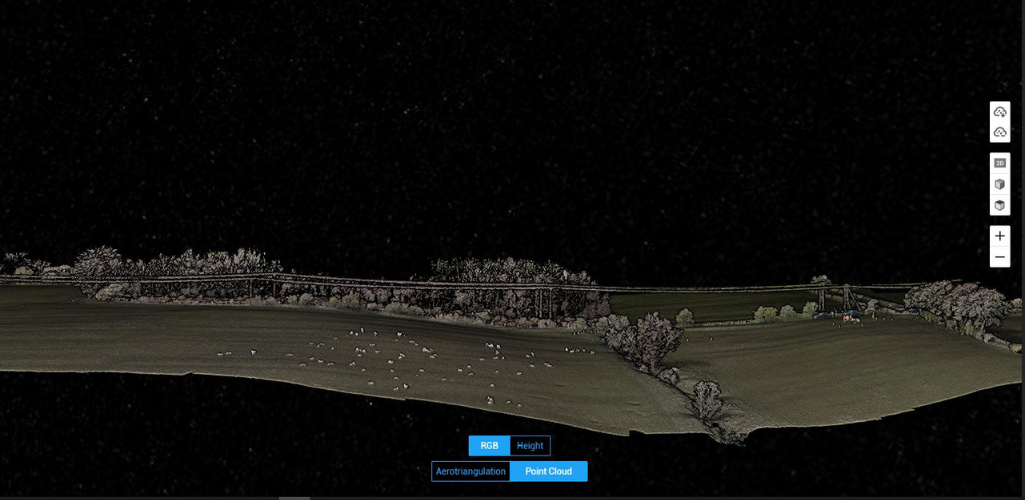

Without a reality model, it is difficult to accurately account for a safety distance between the power lines and buildings in the vicinity during the design phase. LiDAR models also enable measurements between powerlines and vegetation, as this image shows below.

The L1 and DJI Terra are proving a reliable solution.

Gordon said: “We have been really impressed with the L1-Terra combination. DJI Terra has been able to created dense coloured point clouds, extremely quickly, and with 2cm accuracy in some areas.”

Post-Construction Surveying With Drones

Aureos is also deploying drones for post-construction surveys, and is again benefiting from efficient and accurate data collection.

Gordon said: “We recently had to conduct a survey focusing on how the ground looked after the project - covering a 1km section of wood poles.

“We deployed our Mavic 2 to capture evidence of the post-construction and it took less than two minutes to cover the 1km stretch. Imagine how long it would have taken to manually capture that information on foot - the difference is night and day!”

DJI M300 RTK: The Weather-proof Drone

One of the key features of the M300 RTK is its IP45 rating, while the H20T is IP44 rated. While this is not a complete waterproofing, the drone and camera are able to withstand prolonged periods of wet weather. And the rugged M300 RTK can also operate in temperatures from -20°C to 50°C.

Gordon said: “We were really impressed with how the drone and camera performed in the rain. They handled the conditions extremely well, with no issues, the quality of the imagery was phenomenal and the majority of the rain was kept off the lenses.”

To further enhance mission safety and reliability, the M300 RTK is hardened against electromagnetic interference from high-voltage lines.

Gordon said: “We operated the drone at a major pylon at the Kincardine crossing in Scotland, which operates at around 275,000 volts. We engaged the drone’s distance lock and the aircraft was completely stable and it sat exactly where it should do with no deviation. It made a big difference."

Working With heliguy™

heliguy™ has supported Aureos in developing its drone programme, including hardware consultancy and supply, and training.

Gordon said: “We couldn’t ask for much more from heliguy™. The support, advice, and service we have received has been second to none.”

Contact heliguy™ by phone or email to discuss how we can support your commercial drone programme.