Thermal Drone Inspections

Safety Enhanced by Thermal Drone Inspections

Enhancing Inspections with Thermal Drones

Thermal drones offer a powerful inspection solution - helping to identify temperature variations that indicate energy inefficiencies, structural defects, or potential hazards.

Drones collect accurate data safely and quickly, resulting in huge cost savings, deeper insights, and more informed decision-making.

These insights provide valuable data for maintenance, safety, and efficiency improvements.

View thermal drones and payloads.

What Are The Benefits of a Thermal Drone Inspection?

Safety & Accessibility: Thermal drones eliminate the need for workers to physically access hazardous or hard-to-reach areas, reducing the risk of injury and minimising the requirement for PPE and additional support like ladders, scaffolding, or rope access.

Cost-Effectiveness: Cover large areas quickly, reducing labour costs and reducing or removing costly downtime. Save money by removing the need for scaffolding, cherry-pickers, or rope access.

Enhanced Detection: Unlike regular cameras, thermal cameras can detect issues such as water ingress points and areas susceptible to mould growth and can alert you of the issue in its early stages, allowing you to carry out preventative maintenance.

Comprehensive Site Mapping: Utilising thermal drones to map your construction site, building, etc enhances the detail you can achieve - as you identify heat signatures, revealing structural anomalies, energy inefficiencies, and potential hazards that traditional mapping may overlook, meaning your maps can enhance project planning and execution.

Industry Applications of Thermal Drone Inspections

Oil and Gas: Thermal drones with obstacle-avoidant features are particularly advantageous for this industry. They can safely fly in and out of tight spaces, detect heat signatures, and provide huge efficiency and resource savings compared to typical inspection methods such as ultrasonic testing and magnetic particle inspection.

Solar Panel Farm: Thermal drones can accurately detect manufacturing defects, such as cracks and faulty interconnectors, and identify temporary shadowing affecting solar panel performance. They do this much faster and safer than a person manually checking and can reduce the hours of manual labour to an hour.

Powerlines: Inspecting powerlines has traditionally been carried out by ground crews or low-flying helicopters, a costly and timely endeavour. With drones, it is faster, but the data you collect can be more detailed as you can zoom much closer in, and thermal cameras can be used to identify hot spots.

Building Management: A drone with a thermal camera is a powerful tool for utility and building inspections. Thermal cameras can spot missing or damaged installations, water under roof membranes, external electrical issues, failed windows, and many other problems.

Best Drones And Payloads For Thermal Inspections

DJI M400 and H30T: DJI's flagship enterprise drone - the DJI M400 boasts 59 minutes of flight time, up to 6kg payload capacity, IP55-rating, power-line-level obstacle sensing, and AR projection. Integrate with the Zenmuse H30T payload - available separately - for thermal inspections.

![]()

DJI Matrice 4T: The DJI Matrice 4T has a thermal camera with 640 x 512 resolution and 1280 x 1024 infrared super-resolution. It also has night-vision, AI capabilities, a wide-angle camera, 3x and 7x zoom cameras, a laser rangefinder, and an NIR auxiliary light. It can fly for 49 minutes.

DJI Matrice 4TD: The DJI Matrice 4TD drone is essentially an IP-rated version of the DJI Matrice 4T, making it especially ideal for public safety and search and rescue operations. It can be used with DJI Dock 3 or deployed as a standalone option without Dock 3.

DJI M350 RTK and H30T: The DJI M350 RTK is the predecessor of the DJI M400. It has an IP55 rating, long endurance, and the ability to carry a range of payloads for mission versatility. Buy the DJI H30T separately or as part of the M350 RTK-H30T combo.

![]()

DJI Mavic 3 Thermal and DJI Mavic 3 Thermal Advanced: The DJI Mavic 3 Thermal is a lightweight, compact, and versatile drone that supports visual data collection, including hybrid zooming, and high-resolution thermal imaging. Its thermal sensor has a 640 x 512 resolution. The drone is also equipped with a 4/3 20MP wide camera and a 12MP tele camera with 56x hybrid zoom, and it can fly for 46 minutes. The DJI Mavic 3 Thermal Advanced is the same as the Mavic 3 Thermal, but has an upgraded thermal camera, offering more accurate temperature measurements, a clearer view at the same distance, and greater range with the same clarity.

DJI M30T: The high-performance DJI M30T has an integrated payload, with 640 x 512 radiometric thermal sensor, as well as wide and zoom cameras, and laser rangefinder. It also has an IP55 weather rating, so it can operate even in harsh weather conditions like rain and snow.

Drone-in-a-box: The Future Of Automated Drone Inspections

The DJI Dock ecosystem enables remote and automated thermal inspections.

The drone-in-a-box stays on-site and is ready to deploy on-demand, for scheduled routine inspections or for unplanned, emergency situations. Data is centralised and can be viewed remotely via software such as DJI FlightHub 2.

DJI's newest drone-in-a-box, the DJI Dock 3, features the DJI M4TD drone, offering a high-res thermal sensor, as well as wide camera, tele and medium tele cameras, laser rangefinder, NIR auxiliary light, and enhanced night vision.

DJI Dock 3 is DJI's first drone-in-a-box that supports vehicle mounting.

It is the successor to the DJI Dock 2 (with M3TD thermal drone), and the original DJI Dock (with DJI M30T thermal drone).

heliguy™ is a DJI Dock partner, offering site planning/installation support, accredited Dock technicians, solutions engineers, SLAs, OSC consultancy for BVLOS operations, and specialist assistance for integrators.

How heliguy™ Can Support Your Drone Inspection Workflows

Consultancy: Leverage the support of our experienced team to start and scale your operations. Obtain proof of concept and advice on the best equipment for your needs.

Hardware Supply and Support: Access a vast stock inventory, focused on but not limited to DJI solutions. Purchase equipment, or utilise the UK's largest drone rental fleet.

Training: Our in-house team of instructors has taught 4,500+ candidates. Obtain your permissions to fly, create robust standard operating procedures, and benefit from industry-specific training.

Drone Assistive Programme: Hybrid training programme, with instructor-led tuition on real-world assets to expand competency during complex asset inspections.

In-house Repairs: Crash support, fault diagnosis, and repairs by our UK-based DJI-trained technicians.

Thermal Drones: Case Studies

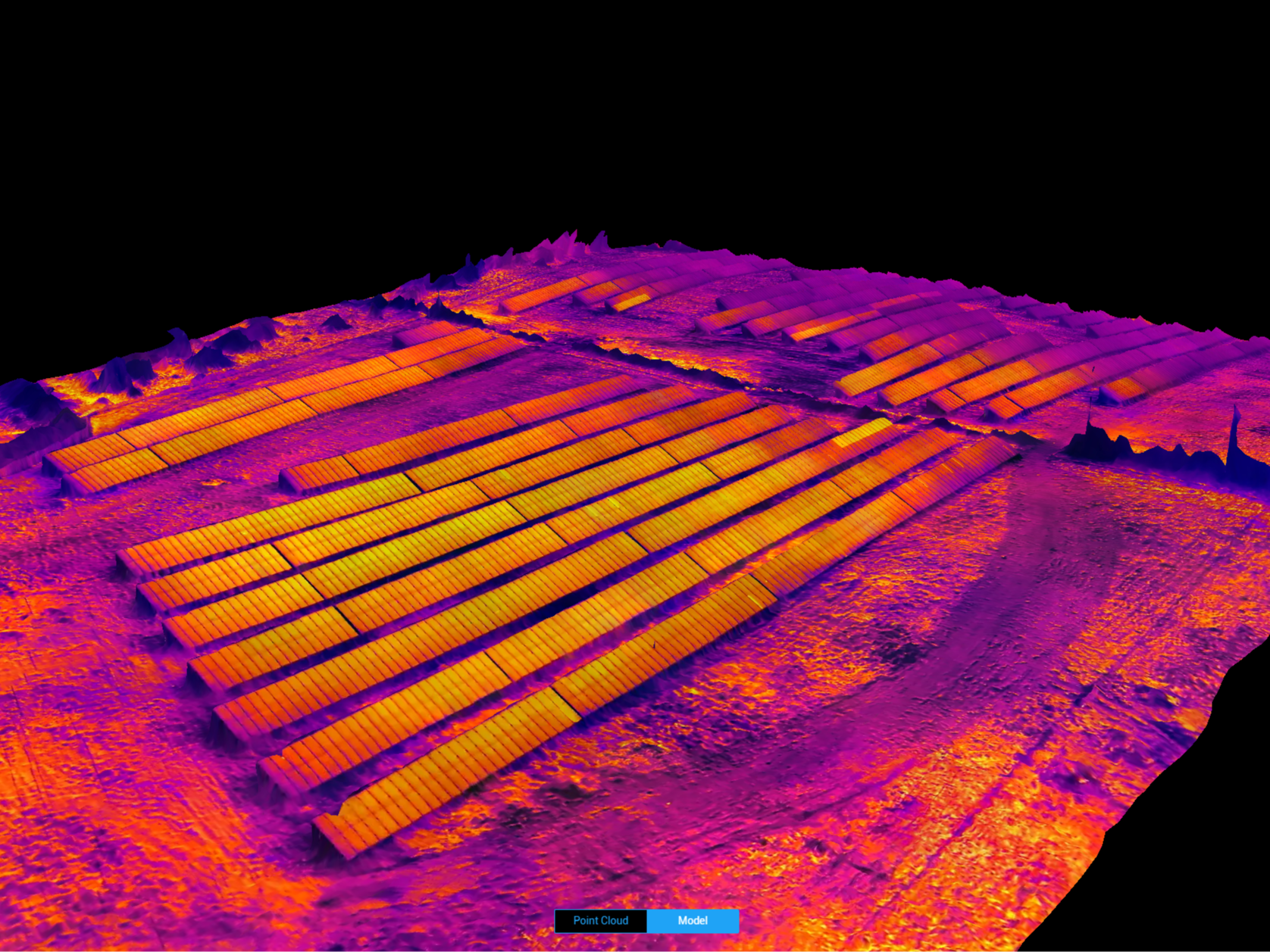

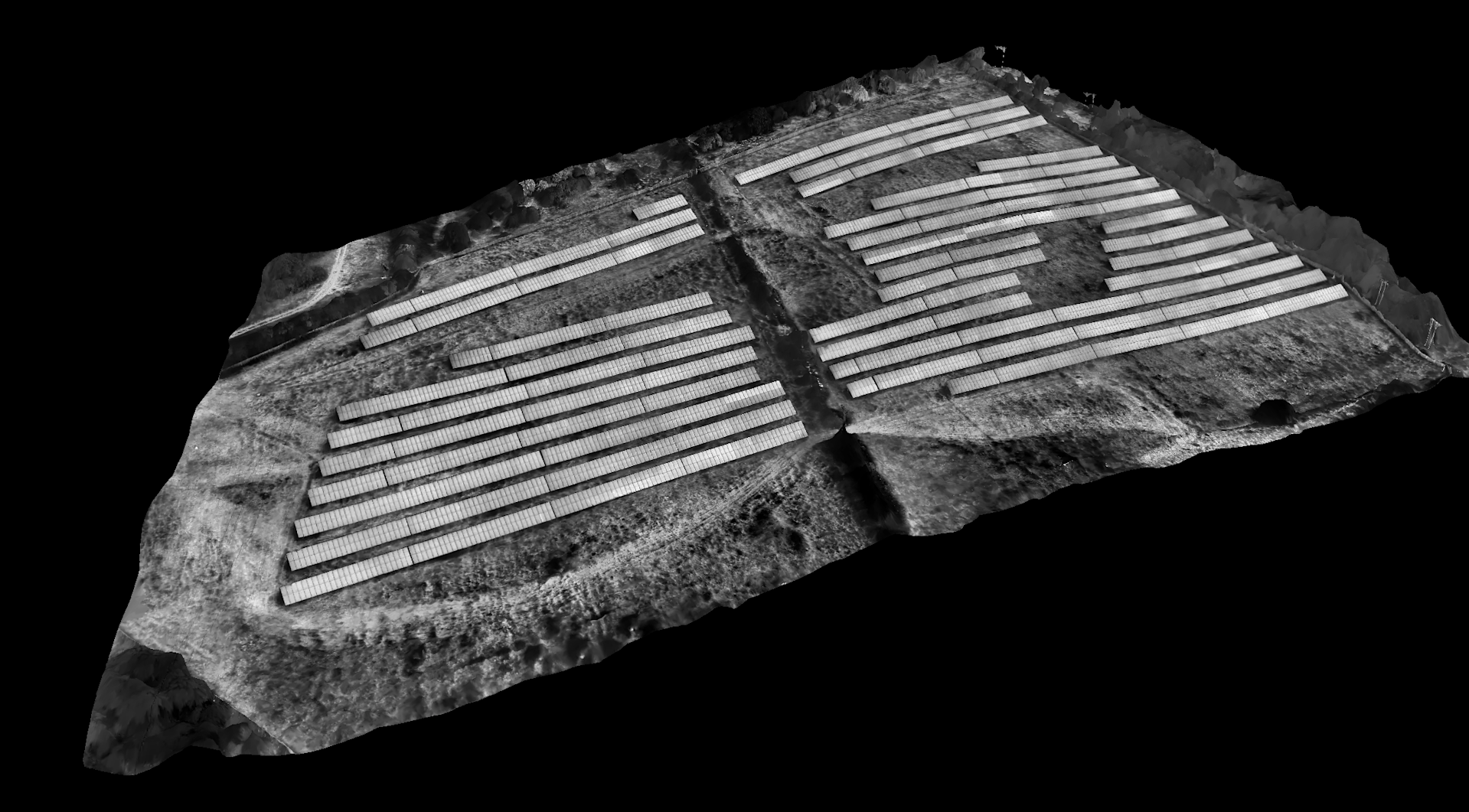

1: Solar Panel Inspection

Durham County Council described the drone-in-a-box concept as a game-changer for solar panel inspections, after trialling DJI Dock 2 to monitor its 3MW solar farm.

Staff have been walking the 23-acre site to conduct manual, handheld inspections - which is time-consuming, can lead to data gaps, and is hindered by accessibility issues in the winter months.

DJI Dock 2 surveyed the site in an hour and 20 minutes - shaving days off the manual methods, provided a view of the entire solar farm in one interactive model, and detected defects and faulty panelling.

The ability to conduct on-demand operations enables more regular inspections - facilitating quicker identification and remediation of equipment-driven underperformance.

2: Utilities Inspection

Engineering firm Aureos deploys thermal drones as part of its inspection arsenal, helping to spot defects or heat abnormalities in powerlines: Issues that would be missed with the naked eye.

Gordon Cranston, Project Construction Manager at Aureos, said: "Through a relatively small investment, drones provide an efficient and effective way of understanding the remaining lifespan of aging assets and determining investment programmes."

Aureos won the prestigious Green Apple World Environmental Award, recognising its use of drones to reduce the company's carbon footprint.